This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Engineering and Operations: Successful Collaboration by Deeper PLM-ERP Integration

In discrete manufacturing, running a business smoothly across departments and functions is challenging, as Engineering, Operations, and Manufacturing all possess highly specialized and complex technical knowledge that needs to be shared efficiently. This proves difficult when Engineering and Operations activities and output data is usually embedded in separate applications poorly integrated, spreadsheets, or even paper trails. As a result, it becomes hard for anyone in the company to get the complete picture of activities and information at any point. Data becomes scattered and hard to trace and backtrack, whereas visibility in end-to-end processes moving across departments is impossible to achieve.

This is especially true for companies designing products for customers, sometimes almost from scratch. More commonly, however, companies use a standard design for the product base and then substantially modify it for the customer’s needs. In addition, many design changes and corrections are made during the process that need to be traceable.

This is where the value of PLM-ERP integration comes in to play.

The Challenges for Design Engineering

- A need to design new features against a deadline

- Constantly changing customer demands

- Sometimes work with subcontracted drafters or design engineers that are less experienced

- Need to respond to problems on the manufacturing floor and in the field that require a quick design change

- Often involved in presales discussions and estimates, conflicting with the deadlines for booked customer projects

- Frequently need to interact with the industrial engineers that create the routings

- Need to communicate with operations regarding rush orders, design changes, problems under warranty, etc.

- Forced to spend about 1/3 of their time on manual non-value added work, such as searching for and recreating data, which detracts their time from the creative work of developing new products.

The challenges for Operations (Planning. Production. Purchasing.)

- Hundreds of new part numbers showing up in the ERP system in a short time span

- Buyers have to get timely price quotes for new items from new vendors

- Buyers are at the receiving end of many BOM changes that cause them to have to place new Purchase orders and/or cancel existing ones

- Production planners and supervisors deal with many revisions that are coming through while production has already started, leading to manual BOM changes on the production orders and sometimes reverse transactions

- Buyers often have to pressure suppliers to deliver within lead time

- Production and Purchasing have to deal with quality problems caused by poor design and communicate these to engineering

- Planning has to make Make/Buy decisions under time pressure

- Planning has to prioritize warranty situations that disrupt the regular schedule

These challenges in Engineering and Operations departments are a lot more manageable when we have much deeper PLM–ERP integration than we usually see. To demonstrate this, we are choosing some critical success factors that are examples of this deep integration between Engineering and Operations.

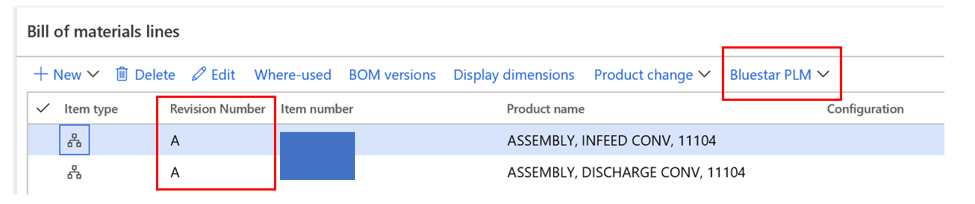

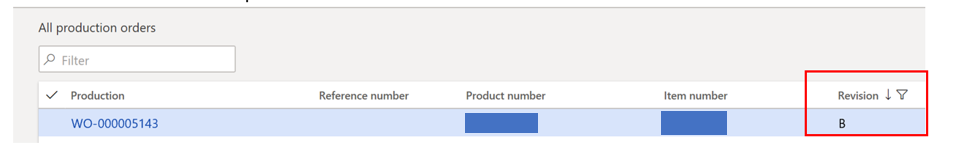

- For operations: Visibility of revision. The revision of an item and a BOM must be visible in the ERP system, including a warning when an item has recently been revised.

- For operations: direct access to design data. For many workers in Operations, it is crucial to have direct access to design data. Because many items are new in each manufacturing project, operations need to find how the part number looks like, as well as see its physical dimensions. The manufacturing floor needs to have direct access to design data to avoid mistakes in assembly or fabrication.

- For engineering: visibility of on-hand and open orders. Engineering has to know the consequences of introducing new revisions: how much on-hand is there, are there open orders. Having this knowledge allows Engineers to coordinate and plan when to release an Engineering Change Order to Operations.

- For operations: Be informed about new BOMs. Operations has to find out as early as possible that a new BOM or even just part of the BOM has been released and that new requirements for part numbers will be forthcoming. This is crucial in order for Purchasing to procure long-lead items early in a project, so Operations and manufacturing will not face the release of an avalanche of parts late in the product that are expensive and take months to get delivered.

- For operations: Know that a BOM is completed. For operations, it is essential to know that the BOM has stopped growing/changing and is now complete.

- For engineering: Be aware that a quality problem has been found. For engineering, it is critical to be informed as soon as possible about quality issues that are related to design.

Commonly seen PLM-ERP integration interfaces

Most manufacturing companies will have some type of interface between their PLM and ERP system. This is often a one-way interface: items and BOMs that are released from PLM are created automatically in the ERP system. This is necessary but not sufficient for a smooth working together of Engineering and Operations.

Introducing Bluestar PLM

In the following, we discuss a much closer interaction between PLM and ERP, as is offered by Bluestar PLM and D365 for Finance and Operations. With that solution, information is centralized in one solution because Bluestar PLM is embedded in Microsoft Dynamics 365 for Finance and Operations. It bridges the gap between Engineering and Operations by bringing your entire enterprise together on the same software platform.

It gives all users access to the same real-time product information, and it improves collaboration between Engineering and Operations, as it provides Engineers the means to easily share design data with Operations, by eliminating redundant manual processes.

This deeper two-way integration between PLM and ERP will be illustrated below using the requirements mentioned earlier.

Addressing Visibility of Revision and Direct Access to Design Data

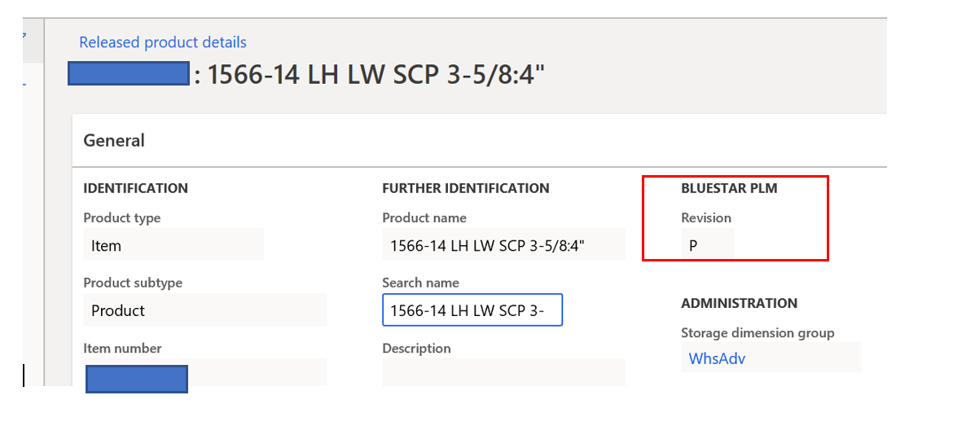

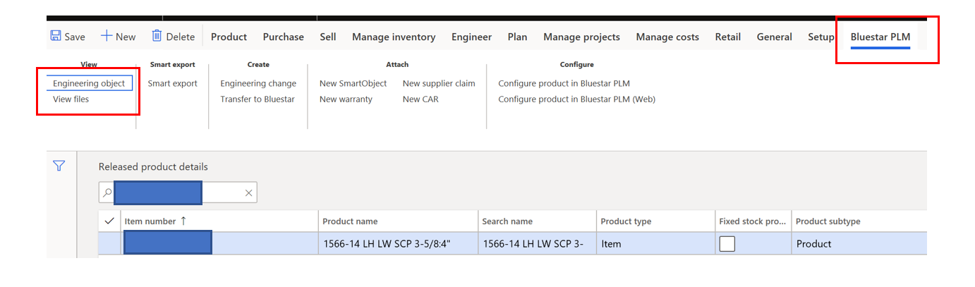

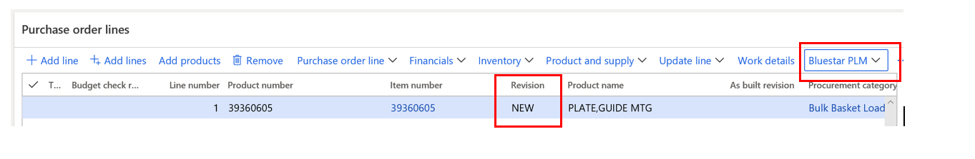

In the Item master (Released product) of the ERP system D365, we see the current Revision of any item that is revision controlled and has a drawing or 3D model in the Bluestar PLM system.

In summary:

- Bluestar PLM provides the current revision on the Released product in D365.

- Sikich’s “ETO power pack” went a step further and shows the current revision of an item in BOM lines, Production order, Prod order BOM lines, and Purchase order lines.

- Bluestar PLM provides direct access from many D365 screens so the ERP user can see design details, physical dimensions.

- Sikich added functionality that warns buyers and production planners when a production order or purchase order line has an old revision (is not the “latest”).

- Bluestar provides an ECO workflow that routes engineering changes to D365 users in Operations.

*Sikich added this as part of a powerpack of functionality for the ETO industry.

Bluestar PLM Workflow

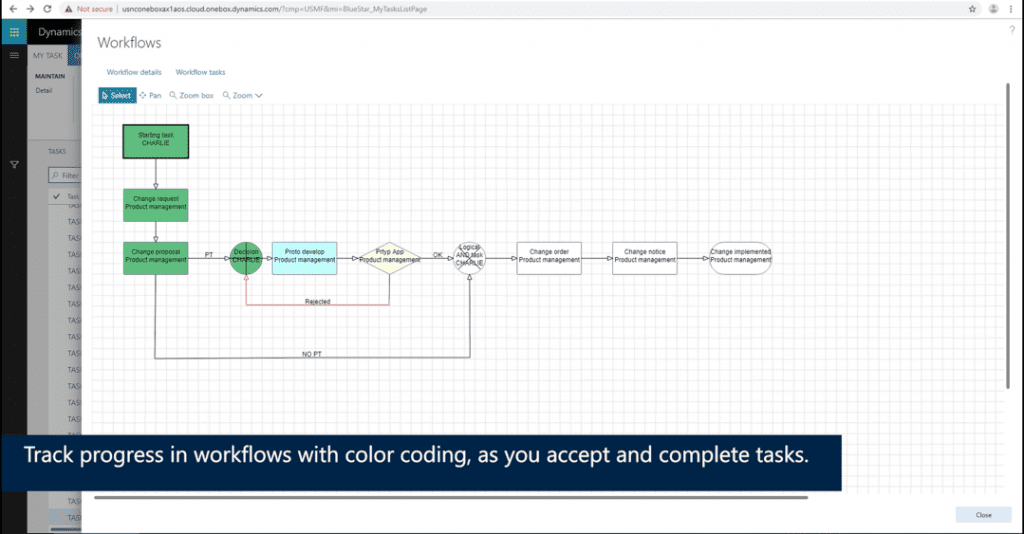

An important feature that addresses these first two requirements is the Bluestar workflow. It can communicate Engineering change data to users in Operations.

In Bluestar PLM, whenever you wish to issue an Engineering Change Order (ECO), the change itself, as well as the change process, is easily defined. When creating a new ECO in Bluestar PLM, it is mandatory to attach a workflow to the ECO, which is used to track the entire change process from request to release. The workflow makes sure the correct people in the organization are reached for the ECO to be defined, approved, executed, and released successfully. Because of the tight integration, the same workflow reaches key people in Engineering and in Operations.

The workflow has a graphic view that shows progress; see below:

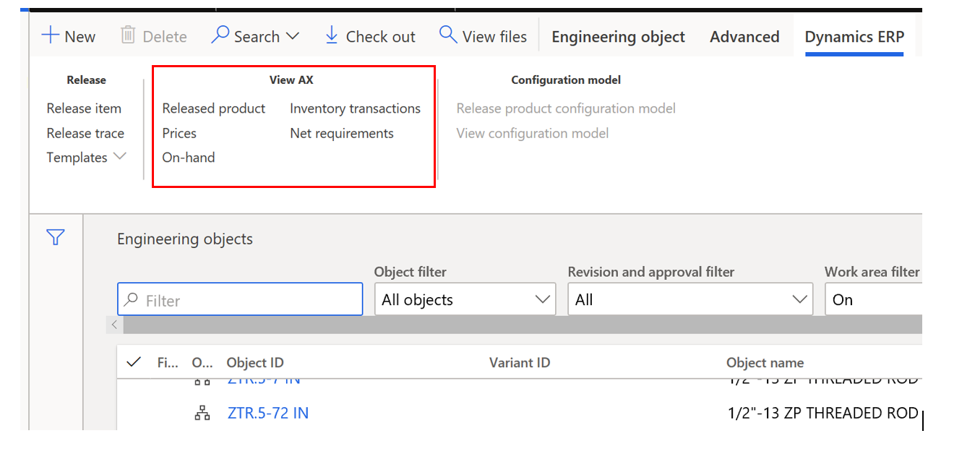

Addressing Visibility of Open Orders and On-Hand Balances for Engineers

In Bluestar PLM , the design engineer can access this ERP information very easily, see below.

While on an engineering object (= the Released product in D365), one can click on any of the choices in the “view AX” section. The following critical business questions can be answered:

- On-hand: “How much inventory do we have right now?” (inventory that may have to be thrown away or reworked when I release a new revision)

- Inventory transactions: “Are there any current orders in process that we would have to put on hold when a new revision is released?”

- Net requirements: “Is the new item / BOM I just released getting planned by MRP?”

Addressing Timely Alerts for New BOMs and When BOMs are Completed

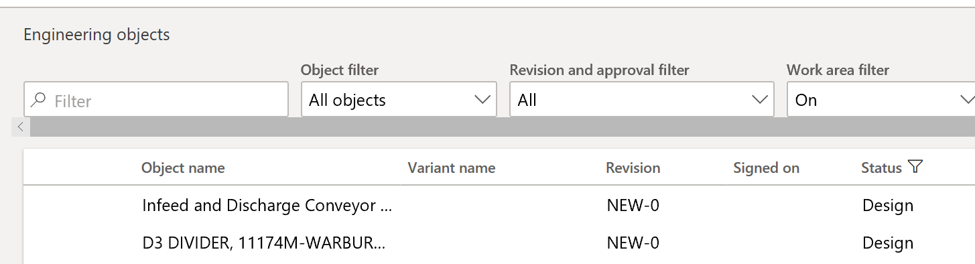

A typical practice in Engineer-to-Order companies is the “Partial release” of Bills of Material. This practice will perfectly illustrate the importance of these two requirements.

In manufacturing companies that build equipment, the “Growing BOM” is one of the defining characteristics. But Operations typically can not wait until the BOM is completed. They have to start buying material right away. That is why we need “Partial release” of the BOM.

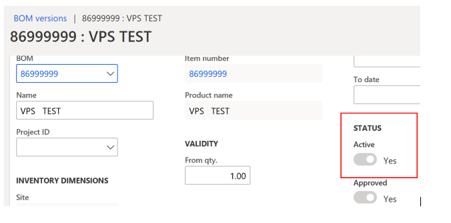

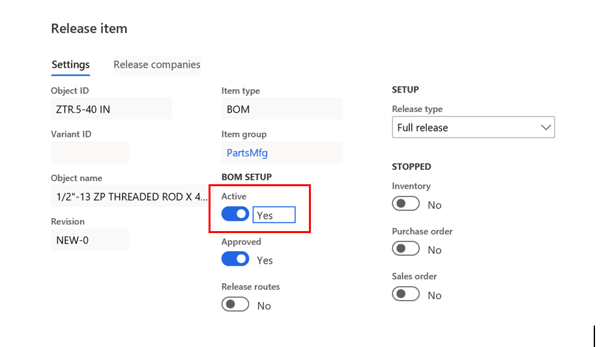

In Bluestar PLM, the design status of that growing BOM would remain “Design,” which allows engineers to continually change the BOM without having to create an engineering change order and a new revision each time. Because there is no ECO and no revision, buyers/planners in Operations would need to be informed via a Bluestar workflow that new parts have been added to the BOM. But even without that, the next MRP run would explode this growing BOM and create additional planned orders for the new items added recently. But this only happens when the BOM in D365 is “active” which makes it important that the engineer who releases BOMs to D365 makes the BOM active right away.

A summary of what is needed for a successful “partial release” process:

- The PLM engineering object should remain in status “Design” until the growing BOM is complete

- The Release to D365 makes the D365 BOM “active” to make sure that MRP will pick up the new demand for new items immediately

- The design engineer uses the Net requirement screen to also get access to the “explosion” screen in D365 so he can verify whether the new parts are getting demand and operations will get new planned orders

- An alert should be setup that is sent to operations when a BOM switches from “Design” to “Approved”. This means that the partial releases have now ended and the BOM is now coming under revision control.

Addressing Quality Problems and Backtracking Them

This requirement is just as important as the previous ones, and the process has urgency when the equipment is already operational. The repair or fix has to be done under warranty.

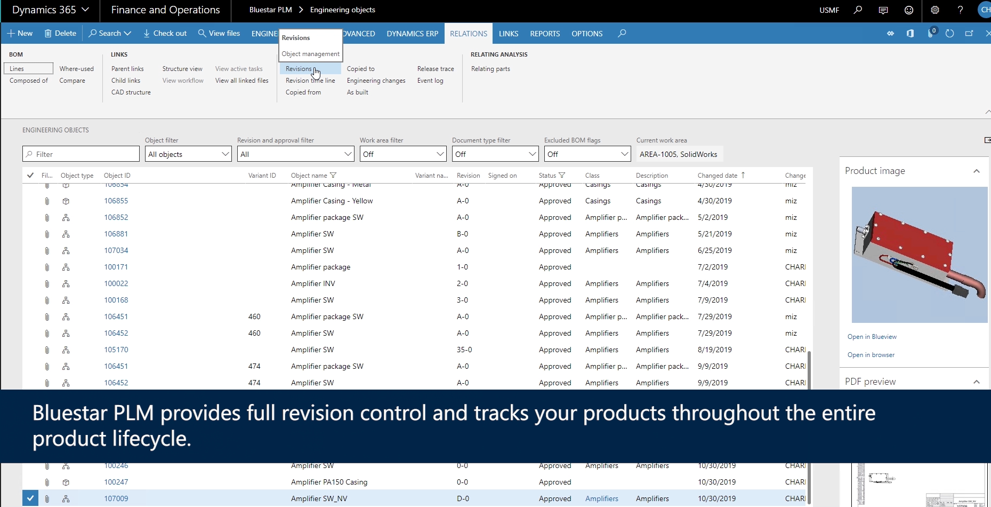

How can Operations view the change in Bluestar when it has been approved and released?

When Operations have received a complaint regarding an item, they can easily view details about the design and the design changes from the Bluestar PLM Vault. From here, they will not only get information on the latest revision, but they will also be able to backtrack all the changes that have happened previously. Users get an overview of all revisions of each product, and the entire trail of changes and responsible connected with the changes:

This is very useful, whenever Operations and manufacturing wish to backtrack, as they are doing quality assessments. They can find out exactly how an error happened at any point during the product’s life-cycle and find out how to fix it.

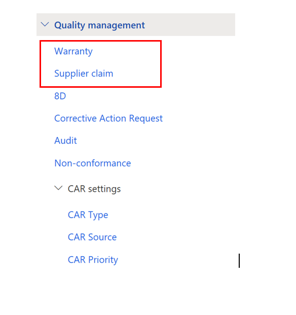

In addition, Bluestar PLM has Quality management functionality with warranty functionality and supplier claims.

PLM-ERP Integration Conclusion

Manufacturing companies nowadays, particularly in the Engineer-to-Order industry, cannot operate efficiently without a PLM-ERP integration. PLM and ERP systems were designed for very different audiences, and their interfaces are often limited to the very basic, such as the Release of new items and BOMs from PLM to ERP. Bluestar and D365 have a much deeper interface, which significantly enhances the efficiency of the entire process from design to shipping, including service. This will lead to reduced errors, rework, and less missed deadlines. The combined PLM-ERP software is supporting an entire business, where complex design data, on-hand, and order data for each item are equally accessible to any user, whether in Engineering or Operations. This is a significant for a successful business in the problematic vertical of Engineer-to-Order manufacturing. It is even more of a success factor for all manufacturing companies that design and build their own designs.

Have any questions about a successful PLM-ERP integration? Contact us at any time!

This publication contains general information only and Sikich is not, by means of this publication, rendering accounting, business, financial, investment, legal, tax, or any other professional advice or services. This publication is not a substitute for such professional advice or services, nor should you use it as a basis for any decision, action or omission that may affect you or your business. Before making any decision, taking any action or omitting an action that may affect you or your business, you should consult a qualified professional advisor. In addition, this publication may contain certain content generated by an artificial intelligence (AI) language model. You acknowledge that Sikich shall not be responsible for any loss sustained by you or any person who relies on this publication.