This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Why Machinery Manufacturers Need Different ERP Solutions Than High Volume Manufacturers

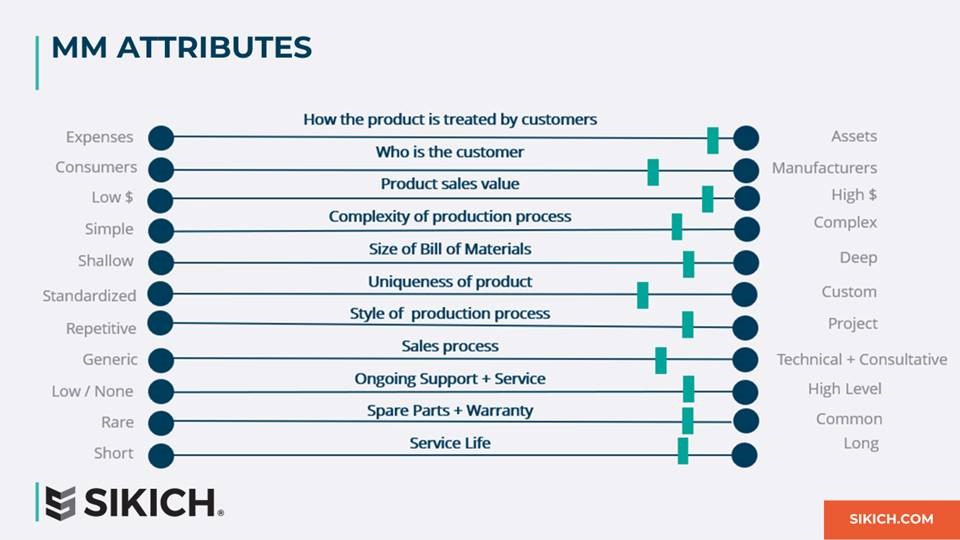

Vertical or industry vertical manufacturers can be called different names, but we often call them engineer to order, equipment, or machinery manufacturers. Regardless of the names, they all make things that are capital investments. They do not create a product you can buy and walk away saying, “See you!”. Machinery manufacturers build specific products for a specific type of customer.

How Machinery Manufacturers Differ From Others

Machinery manufacturers create products that are not easy to build, take time to design, need a specific definition, and fit a particular customer’s situation. Often, you have to go and see how the customer is going to use that product and where they will use it before you can design it correctly. So, there is a specific complexity in the products, but also an extended longevity. This product is not supposed to be used after two years and be replaced. Instead, we typically talk about decades. That is why we say these products are capital investments.

In addition, the typical customers for these products are also manufacturers. They usually have a big operation that requires big machinery, so it’s a B2B sale, obviously. Engineers from both sides of the sale talk back and forth regarding what they want the machine to do as well as what is possible for customizations. These products can easily reach a $1 million price point before you know it, but again, it is an investment.

Because it is an investment, we’re seeing more and more customers that want to track the life cycle costs of these equipment purchases, which is just as true for our own customers using our software. Since these manufacturing customers are investing in a product that will support their manufacturing operation for decades, it’s not only about what they must pay to build the machine and install it; it’s also what they will pay long term, including the spare parts, the maintenance, etc.

How the Machinery Manufacturer Product Process Differs

When it comes to bills of material, machinery manufacturers do not have a simple bill of material. They’re often complex and deep. Many times, As expected with these engineered-to-order products, they contain a lot of single-time use part numbers that will never be seen again. These manufacturers will have a massive file on part numbers, which puts additional pressure on processing times of MRP. One hundred thousand-part numbers in the ERP system is nothing for this type of manufacturers and may not seem like much, but we have seen much more. Because of the long service life, part numbers have a long life in the ERP system also. There could also be a new demand for a very old part number.

It’s really the style of the machinery manufacturing production process that poses the biggest challenge for ERP systems. It is project manufacturing. It’s not just engineers and professionals working on these projects. The very production process is project-based. We can’t forget the labor on the shop floor that factors into the production process. For an ERP system to truly benefit machinery manufacturers, it needs to be able to tap into everything going-on on the shop floor. For example, an ERP system needs to be able to show how many hours did a laborer spend welding for this specific equipment order for this one customer. This shop floor insight is exactly where Sikich specializes. These manufacturers have a project margin to protect, instant insight in actual labor for each project is critical.

How the Machinery Manufacturer Sales Process Differs

The sales process obviously cannot be quick. There’s long negotiation back and forth. What is interesting, though, is that often customers of machinery manufacturers learn a lot about their own operation when ordering equipment. Of course, they also learn a lot about the new equipment they are about to buy, which means that the sales process is quite long, with many different variations of the quoted price.

As a result, the sales process is definitely an engineering process. The price is just a tiny little thing at the end.

Then we have the critical piece that is not so hard for an ERP system: customer support after-sales. The true excitement begins after the sale, because this brand-new piece of equipment is going to go through a lot of upgrades, changes, and unavoidably some fixes. Sometimes engineers find out something that they can do better after the fact. With these products, the manufacturer is far from done after shipping and installing the equipment. That’s why manufacturers have long relationships with their customers that go easily into the decades, because once you have an equipment like that, it’s not like you’re going to change brand names the next time you need something. Most likely, you will want to stick with it and just make it better and better to fit your business better and better.

Machinery Manufacturers Keep Long Customer Relationships

And thus, enter the spare parts business. Our customers in the equipment industry typically make a lot of money on spare parts. The margins on that are predictable and high. Our machinery manufacturers must try to prevent their customers from buying generic parts at Home Depot or generic parts from the original equipment manufacturer. That is sometimes a challenge, but very often, the components are engineered, so there’s a substantial profitable business on the spare parts business alone. Of course, machinery manufacturers will need to have a database of their sold equipment in their ERP systems, with “as built” details regarding serial numbers and revisions This includes solid functionality for warranty tracking as well.

During this long service life of their products, machinery manufacturers can always create additional opportunities. For instance, most of these manufacturers’ new quotes are for existing customers. With our own manufacturing customers, the percentage for new quotes for new customers falls between 10-20%. That’s unique to this type of manufacturing industry.

Sikich specializes in customizing ERP systems to be able to address all of the needs of machinery manufacturers. Be sure to check out our next post on the machinery manufacturer’s checklist for ERP. Of course, if you have any questions about how Sikich can engineer-to-order our ERP products for your manufacturing business, please contact us at any time!

This publication contains general information only and Sikich is not, by means of this publication, rendering accounting, business, financial, investment, legal, tax, or any other professional advice or services. This publication is not a substitute for such professional advice or services, nor should you use it as a basis for any decision, action or omission that may affect you or your business. Before making any decision, taking any action or omitting an action that may affect you or your business, you should consult a qualified professional advisor. In addition, this publication may contain certain content generated by an artificial intelligence (AI) language model. You acknowledge that Sikich shall not be responsible for any loss sustained by you or any person who relies on this publication.