This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Infographic: Overcoming the demand change challenge

The next pandemic or comparable disruptive event that causes sudden changes in demand does not need to come as a surprise to manufacturers. With the right intelligence and technology tools, you can rebuild demand management and strengthen your relationships with manufacturing customers and vendors to thrive through whatever challenges come your way.

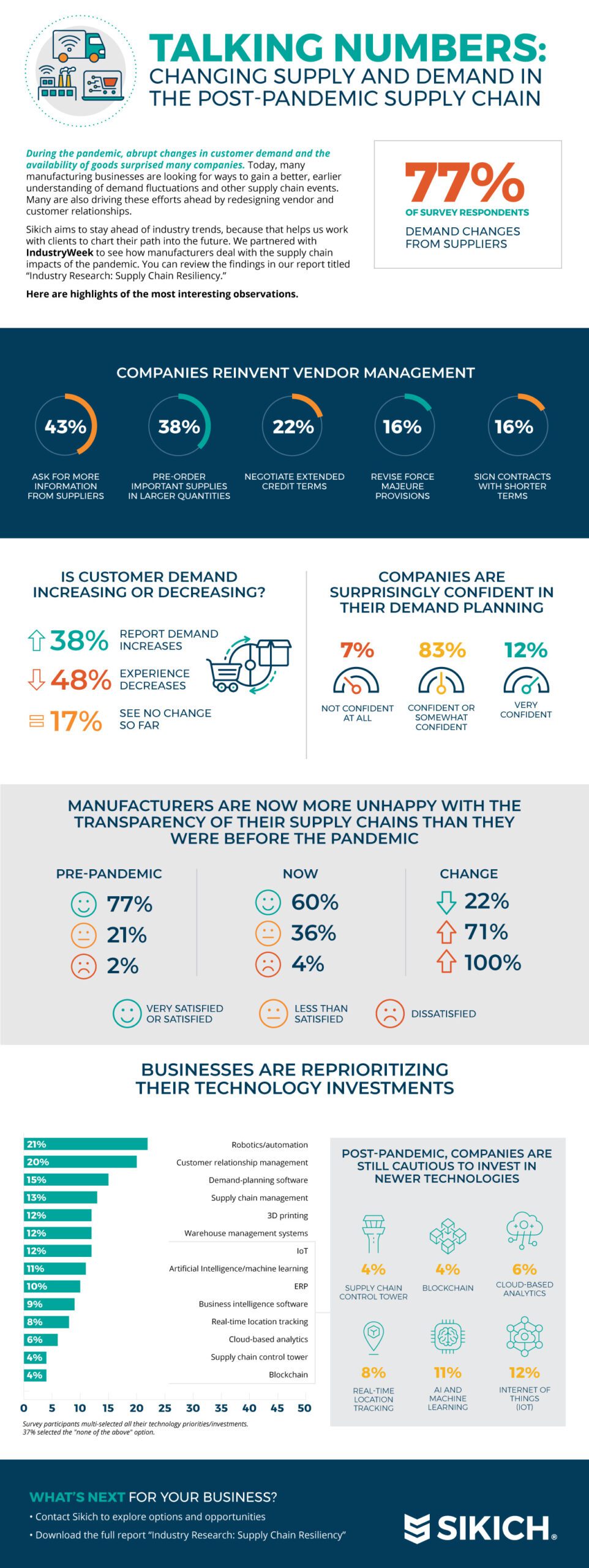

When the pandemic caused sudden changes in customer demand, companies found it difficult to keep up. Pictures of empty store shelves only told a part of the story. When Sikich partnered with IndustryWeek to survey manufacturers and find out how their supply chain management is changing during and after the pandemic, we learned that 61 percent of the respondents missed customer shipments or only got them out late. Manufacturers’ vendors delivered 73 percent of their shipments late.

When just-in-time manufacturing becomes a constraint

Many manufacturers have practiced just-in-time production and supply chain management for many years and with great discipline. When unplanned disruptions or dramatic demand changes are only minor concerns, the just-in-time approach can be very effective in keeping operations lean, fast-moving, and cost-efficient without jeopardizing customer commitments. From time to time, earthquakes and dramatic climate events have demonstrated that very lean supply chains and minimal inventories can make companies vulnerable, but those were typically not global occurrences. The pandemic, on the other hand, impacted supply chains worldwide. For many companies, it came unexpected, and their analytics and modeling tools did not allow for its scale. Customer demand for certain goods changed rapidly and dramatically, and manufacturers operating with ultra-efficient, just-in-time processes and small inventories could not adjust quickly. Business customers and consumers had to find other providers or go without.

Assessing vendor management and looking for more demand insight

Manufacturers did not wait to act. Seventy-seven percent responding to our survey are changing how they engage with suppliers. Many of them are asking for more information from their trading partners or are renegotiating contracts. In many organizations, vendor management might be one area where it is relatively easy to isolate and identify issues that could be remedied.

Only a small minority reported that they had not experienced any changes in customer demand. Eighty-six percent had seen increases or reductions. Considering what we know about delayed and missed shipments, it may seem surprising that 95 percent state that they are “very confident,” “confident,” or at least “somewhat confident” in their demand-planning capabilities. However, at the same time, the survey shows a 71 percent increase in the number of manufacturers who are not satisfied with the transparency of their supply chains. A fast-moving 17 percent are already investing in solutions to increase their supply chain visibility.

You’ll notice that the survey results look inconsistent. At least some of the manufacturers indicating some level of confidence in their demand planning are likely also not satisfied with their supply chain visibility. Adopting more real-time and comprehensive supply chain insight tools would probably be a good recommendation for many manufacturers. You need to gain the best possible intelligence regarding all aspects of your supply chain—vendors, logistics, customer demand, changes in business rules imposed by large trading partners, regulatory updates, and social and environmental conditions. You should also have a way to correlate these findings in the context of your financials, business performance, product planning, and sales initiatives.

Enabling business insight and great customer and vendor experiences

Today, manufacturers can rely on a modern ERP system as their main resource for managing supply chain and other business processes, as their system of record for data from all sources, and as their system of engagement for vendors and customers. Sikich has helped many hundreds of manufacturing clients to get the right results from such ERP solutions as Microsoft Dynamics 365, which provides ample capabilities in all three of these areas. They can use the solution’s customer relationship management (CRM) capabilities to both serve customers and engage with their vendors.

Many also provide customers and vendors with secure portals, where they can review products, submit invoices, make payments, and take care of other business functions at their convenience. When manufacturers, as they told us in the survey, ask vendors for more information or want to revisit terms, it may also be in their best interest to be more collaborative and make it easier for suppliers to do business with them. Even offering streamlined communications through electronic document interchange (EDI) can make a difference in the quality of the engagement. EDI is a technology Sikich often adds to Dynamics 365.

Dynamics 365 ERP includes demand planning and forecasting functionality. Sikich can enhance it with vetted, proven solutions for manufacturers’ specific requirements. We can also help you maintain inventory at healthy levels without tying up funds unproductively or keeping it so minimal that you inadvertently cause a constraint when demand fluctuates.

Innovating ahead of the competitive pack

One interesting observation in our survey was that many manufacturing companies are not yet using newer or more advanced technologies in their supply chain management. For example, just 6 percent use cloud-based analytics and 11 percent rely on artificial intelligence (AI) and machine learning. Twelve percent use internet of things (IoT) solutions to track shipments, vehicles, and containers; monitor environmental conditions during transport, in warehouses, and in production facilities; or keep tabs on the performance and wear-and-tear of industrial equipment.

Until the field catches up, that means you might be able to create a strong competitive advantage with cutting-edge technologies. For instance, you could use AI- or IoT-based analytics to better assess customer demand and supply chain trends. Equipped with that insight, you might outperform the competition in the timely production and delivery of what customers want.

Next steps

If you want to bring greater intelligence and flexibility to demand planning and supply chain management, here are some things you could start with:

- Contact Sikich to explore options and opportunities.

- Download the full IndustryWeek and Sikich report “Industry Research: Supply Chain Resiliency.”

This publication contains general information only and Sikich is not, by means of this publication, rendering accounting, business, financial, investment, legal, tax, or any other professional advice or services. This publication is not a substitute for such professional advice or services, nor should you use it as a basis for any decision, action or omission that may affect you or your business. Before making any decision, taking any action or omitting an action that may affect you or your business, you should consult a qualified professional advisor. In addition, this publication may contain certain content generated by an artificial intelligence (AI) language model. You acknowledge that Sikich shall not be responsible for any loss sustained by you or any person who relies on this publication.