This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Advanced Warehousing Replenishment Strategies and Configurations in Microsoft Dynamics 365 Supply Chain Management

“Hey forklift driver Joe, can you come over to aisle 10 and drop down some goods from the top overflow rack?” The point of this article is for warehouse pickers not to make this radio call and have Microsoft Dynamics 365 Supply Chain Management advanced warehousing replenishment routines create the replenishment work to be completed. In this article, coauthored by my colleague Jerry Von Eberstein, we will review the configuration of the two most common forms of replenishment strategies in advanced warehousing: Min/Max and Wave demand. Min/Max uses minimum and maximum stocking limits to determine when locations should be replenished, and Wave demand creates replenishment work if the quantity that is required for a sales order isn’t available when a wave is processed.

Min/Max Replenishment

As noted above, Min/Max replenishment is a method of replenishing inventory based on predefined minimum and maximum levels for each item and location. It helps to optimize inventory levels, reduce stock-outs, and improve customer service. In Microsoft Dynamics 365 (D365) Finance and Supply Chain Management, you can configure Min Max replenishment for advanced warehousing by using the following steps:

- Define the replenishment template and type.

- Set up replenishment for advanced warehousing.

- Assign the replenishment template to items.

- Run the replenishment template to create work.

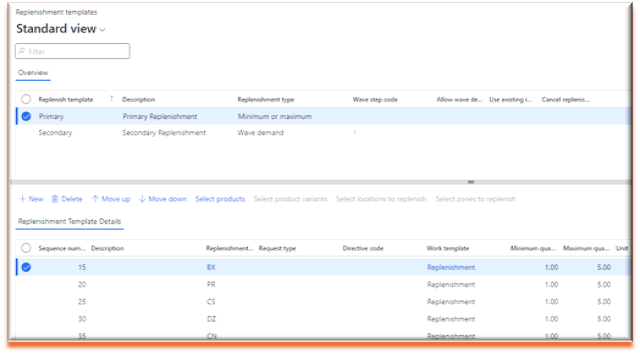

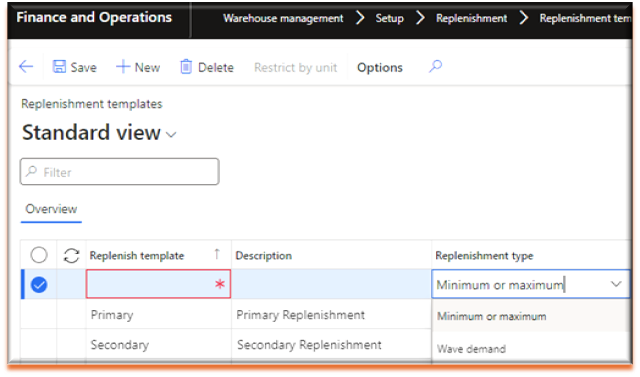

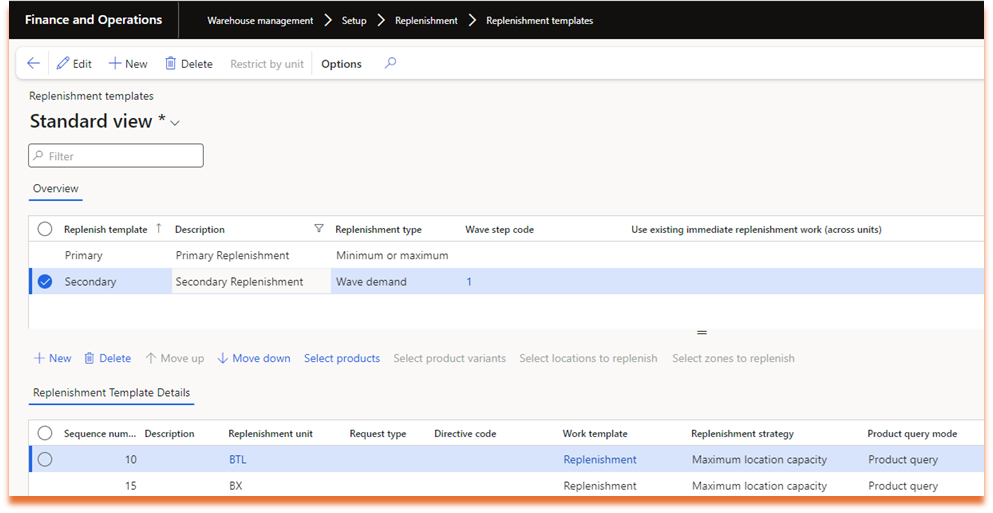

A replenishment template is a set of rules that define how the replenishment work is created. You create multiple replenishment templates for different scenarios and assign to different items and locations. Ensure you have selected Min/Max for the replenishment strategy and the replenishment zone, the minimum and maximum quantity, the rounding option, and the unit of measure for the replenishment. Work templates and location directives are optional but support very detailed scenarios.

Pro tip: One of the most challenging parts of this process is having to create a min max for each replenishment unit. This is the smallest unit that will be used to specify quantities in the generated replenishment work. However, the work creation process will always use the largest appropriate unit available within the matching unit sequence group, which means that replenishment work lines may often use a larger unit. This will likely require a bit of data mining and planning to achieve this integral piece.

Set up Replenishment for Dynamics 365 Advanced Warehousing

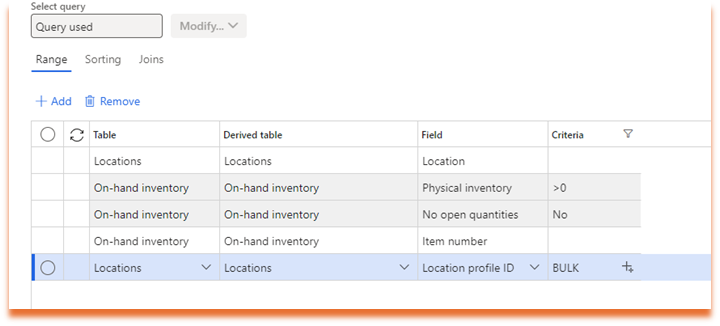

If you are using fixed locations for items, this would allow stock to be replenished even if it falls below the minimum level, because the system can determine which items need to be replenished, even if there aren’t any left. Create replenishment location directives that are used to determine where items should be picked from in the replenishment process. Use the query to add restrictions where inventory can be selected from in the replenishment process. Work templates are used to guide the system as to how the min/max replenishment work must be created. At a minimum, there must be a work template line for a pick and a put. Create the replenishment template, name it something creative such as “Min-Max Replen,” and choose the appropriate type. We will discuss Wave demand later in the article.

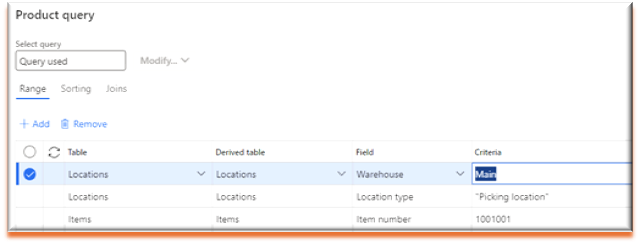

Next users must assign the replenishment template to the items and locations that you want to replenish. Select the warehouse, the item, and the location that you want to assign the replenishment template to using a query builder from the template. You could also use item groups or other creative ways to assign the query.

The final step is to run the replenishment work creation process that generates the replenishment work orders based on the replenishment template and parameters. You can run the replenishment work creation process manually or schedule it to run automatically via batch process.

Wave Demand Replenishment

This strategy creates replenishment work for outbound orders or loads if inventory isn’t available when the wave creates work. For example, replenishment work can be created if the quantity that is required for a sales order isn’t available when a wave is processed.

To configure wave demand replenishment in D365 Supply Chain Management advanced warehousing, follow these steps:

- Create wave template with replenish method and step code.

- Create the replenishment template and define type as wave demand.

- Create replenishment location directives.

- Test the configuration.

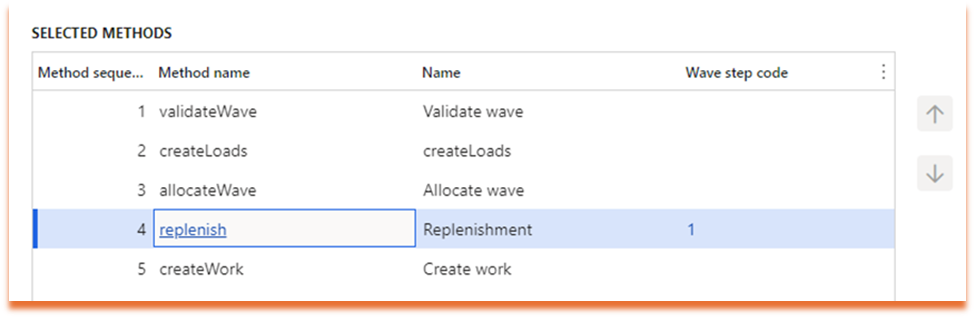

A wave template determines what happens when the wave is processed. You can have multiple wave templates to handle different scenarios. For example, A wave of orders may need to be created because the orders in that wave are bulky and require special handling. When the wave is processed, the specific wave query and configuration will determine which orders are included in the wave. Wave demand replenishment requires that you add the replenish method to the selected methods. Also, you must identify a wave step code on the wave template. The wave step code will tie the wave template to the replenishment template.

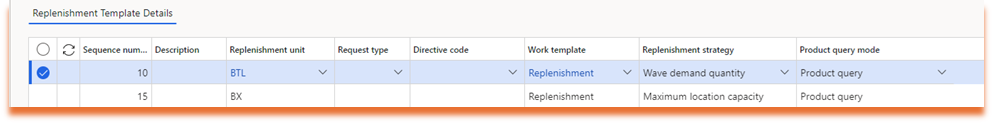

A replenishment template is a set of rules and parameters that define how the replenishment work is created and executed. Create a new replenishment template and ensure that wave demand is selected for the replenishment type. Also, select the wave step code that was created in the previous step. Under replenishment template details, create a new line and add a sequence number, replenishment unit, work template, replenishment strategy, and product query mode.

Pro Tip: Two Options are Available for the Replenishment Strategy.

- Wave demand quantity will generate replenishment work to match the required demand.

- Maximum location capacity will generate replenishment work to fill the location based on the stocking limit. This option can potentially increase efficiency by reducing repeat replenishment work.

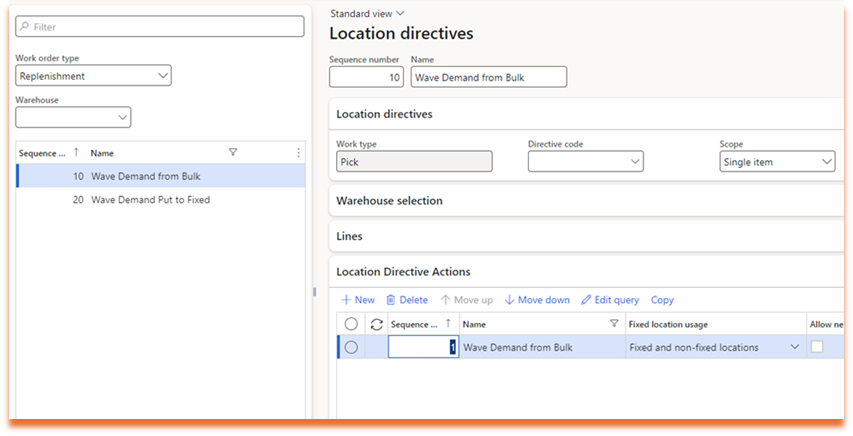

Next, we need to create pick and put replenishment location directives for wave demand replenishment.

Define the pick and put criteria for the location directive actions. The queries for each will determine where items should be picked from and put (placed) in the replenishment process.

The final step is to test the configuration. Identify an item and ensure adequate inventory exists in a bulk/overstock location. Check the inventory in the fixed location and adjust if necessary. Next, create a sales order containing enough of the item to deplete the inventory in the fixed location. Release the sales order to the warehouse and process. Replenishment work should be created, based on the replenishment template, to either fulfill the demand or to fill the location to the maximum stocking limit.

Thank you for your time and hope these Dynamics 365 Supply Chain advanced warehousing strategies and configuration tips on replenishment help improve your warehouse efficiency. If you have questions, reach out to Sikich for help.

This publication contains general information only and Sikich is not, by means of this publication, rendering accounting, business, financial, investment, legal, tax, or any other professional advice or services. This publication is not a substitute for such professional advice or services, nor should you use it as a basis for any decision, action or omission that may affect you or your business. Before making any decision, taking any action or omitting an action that may affect you or your business, you should consult a qualified professional advisor. In addition, this publication may contain certain content generated by an artificial intelligence (AI) language model. You acknowledge that Sikich shall not be responsible for any loss sustained by you or any person who relies on this publication.